Pocket Tracker Insider – Issue #2

The lab has been buzzing lately: from production finishing touches to 3D printed kit.

Hey! I’m Gabriele, a freelance embedded developer from Italy and this is the second issue of the Pocket Tracker Insider newsletter.

If you missed Issue #1 or you don’t see this newsletter properly, you can check it out HERE. I’m back with some exciting updates on production, new features, and a sneak peek at what’s coming next.

Thanks for being here. Let’s get into it!

Today’s Topics:

🔧 Production Status – Almost There!

🚀 How Production Works (Quick Behind-the-Scenes)

🧰 3D-Printed Kit – Build It or Print It Yourself

🔍 Dev Zone – Inside the Pocket Tracker

🙌 Thanks & What’s Next

1. Production Status – Almost There!

As you might remember from Issue #1, I kicked off the production of the first Pocket Tracker batch a few weeks ago. By the time you're reading this, the process is likely in its final stages—or even finished!

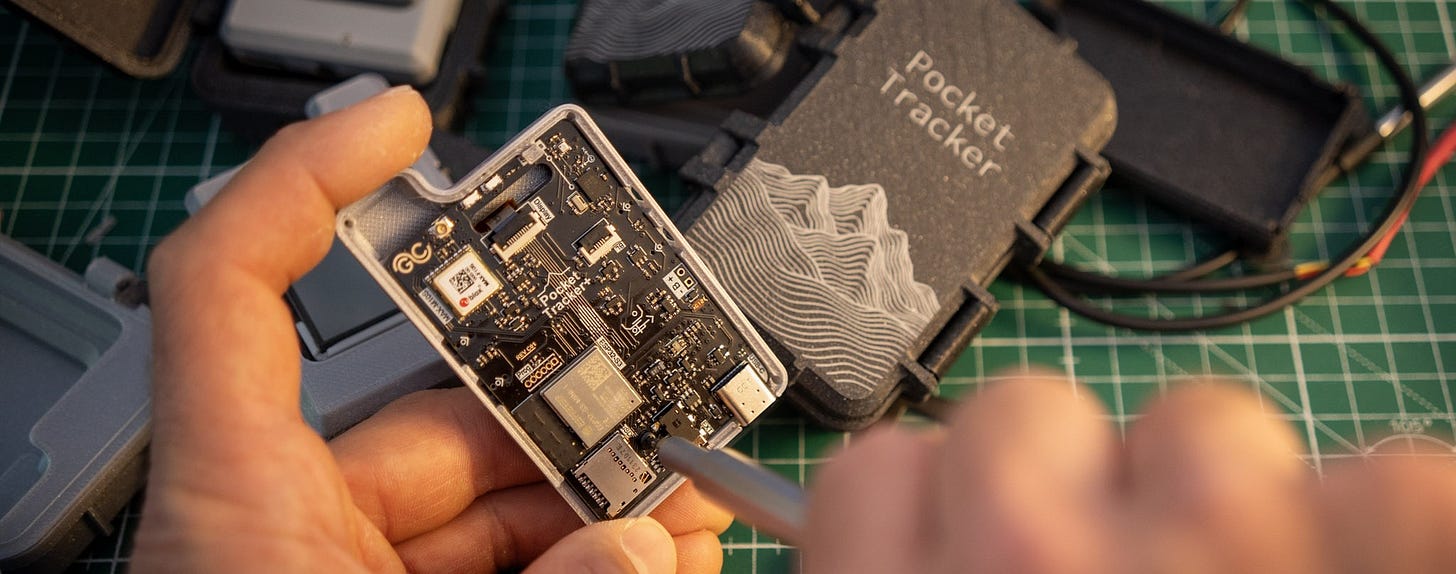

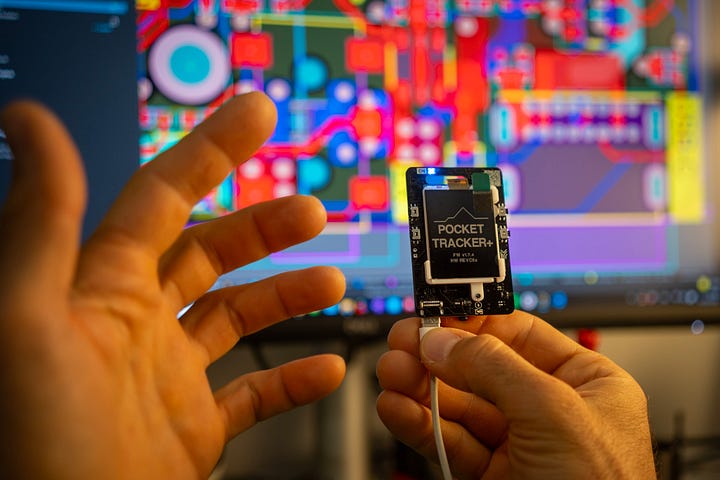

This just in from the Elecrow assembly line: a short video showing the Pocket Tracker being brought to life! It’s super exciting for me to watch components being placed on a board I designed — and I thought you’d enjoy it too.

A Small, Big Decision

Starting production was a “big” decision for me—even though I'm only making a small quantity. It’s not easy to put your own money into something when you don’t know exactly how it will go. But honestly, it’s because of you that I went for it.

Your interest, encouragement, and messages made me think: it’s worth trying.

No matter how it goes, I’m already happy with the outcome. I’ve learned a lot and had fun along the way. That’s already a win.

What You’ll Get (and Where to Get It)

I'm happy to announce that the Pocket Tracker electronics will be available soon on the Elecrow online store. I’ll share the direct link in the next newsletter (and on Instagram too). You’ll have two options:

PCB Only – $130

PCB + Display – $150

(Note: The version with the display doesn't include the frontlight—it’s been out of stock for a while now.)

2. How Production Works (Quick Behind-the-Scenes)

I thought some of you might find it interesting to know how small-scale production like this works—especially if you’ve never done it before. In my case, it’s surprisingly straightforward, but with some key things to keep in mind.

🗂️ Step 1: Preparing Files

You need to send the manufacturer a set of documentation that includes:

Gerber files (for PCB manufacturing)

Pick-and-place file (for automated assembly)

Detailed BOM (Bill of Materials)

Since my PCB has a very minimal silkscreen (for aesthetic reasons), I also sent reference photos of the assembled board and a 3D model for the display holder. That part is 3D printed and assembled by Elecrow for the display version.

💬 Step 2: Manufacturer Feedback

After submitting the files, Elecrow got back to me in a few days with a detailed quotation. If you’ve ever ordered just a couple of prototypes, you’ll know that prices can be quite high. But as you increase the quantity, the cost per unit drops—especially for components.

In my case, I didn’t produce enough to hit big discounts, but that’s okay. This batch is an experiment. If it goes well, I might increase the volume next time and benefit from bulk pricing.

📌 Pro Tip: You usually start seeing meaningful price drops once you go over 100 units. That’s when sourcing and logistics start to scale better.

✅ Testing Matters

Another essential part of the process is making sure the boards are tested properly. I created a small Test firmware that Elecrow can flash onto the boards after assembly. It checks all the peripherals and reports back the results, so their operators can fix anything if needed.

Remember: these people are skilled, but they don’t know your device. The more you document and explain, the fewer surprises you’ll face—and the smoother everything goes.

3. 3D-Printed Kit – Build It or Print It Yourself

As I mentioned in Issue #1, I’m releasing the 3D printable files for the Pocket Tracker enclosure. So if you have access to a 3D printer, you'll be able to print everything yourself and build your own case.

But that’s not all.

I’m also working on something a bit more special: a complete 3D-printed kit that you can purchase directly from me to support the project. This kit includes much more than just plastic parts—it’s been carefully refined through many iterations to give your Pocket Tracker a finished product feel.

🎁 What’s Inside the Kit:

Precision 3D-printed parts, laser-engraved for a clean, professional look

A polycarbonate screen protector, for added durability

A dedicated antenna matched for best performance

A battery connector, in case your battery has a big connector that doesn’t fit the slim case

All the small essentials: mounting screws, LED optical guides, adhesive, and foam, to assemble everything the way I’ve optimized over time

💼 The Rugged Case – Personal, Durable, and One-of-a-Kind

The real highlight of the kit is the custom rugged case, designed specifically to protect and carry your Pocket Tracker.

This isn’t a generic box. It features:

Laser-engraved graphics I personally designed

A sequential module number, giving each unit its own identity

A durable dual-color finish, inspired by the Pocket Tracker’s look and feel

A precision-cut interior to hold everything securely in place

This case turns the Pocket Tracker from a dev board into a real gadget you can throw in your bag without worry.

❌ What’s Not Included in the Kit

To keep things clear, here’s what you’ll need to source separately:

🧩 Pocket Tracker PCB (with display)

You’ll purchase this directly from Elecrow’s store once it's available.💾 microSD Card

Recommended: 32GB, formatted as FAT32 for full compatibility with the ESP32-S3.🔋 Battery

The enclosure is designed to fit small single cell LiPo batteries with a maximum size of 6.7 × 42 × 61 mm.The battery I’m using is this one [LP674261] and here is a list of compatible batteries:

🖨️ Want to Start Printing Early?

Do you want to start printing your case, run some experiments, or just get a head start while waiting for the electronics to be available?

Reach out to me, and I’ll be happy to send you the 3D files in preview for free before the official release.

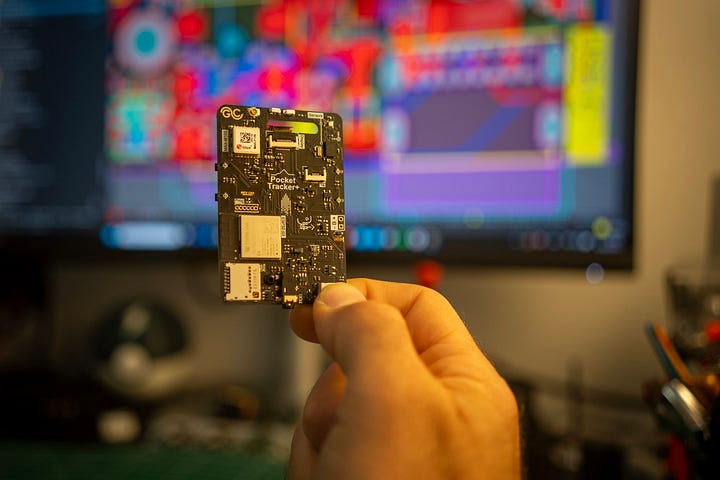

4. Dev Zone – Inside the Pocket Tracker

And finally… let’s get into some developer-focused content.

Since we're getting closer to the moment when some of you will have the hardware in your hands, I want to start sharing more technical details so you can begin thinking about your own custom applications and ideas.

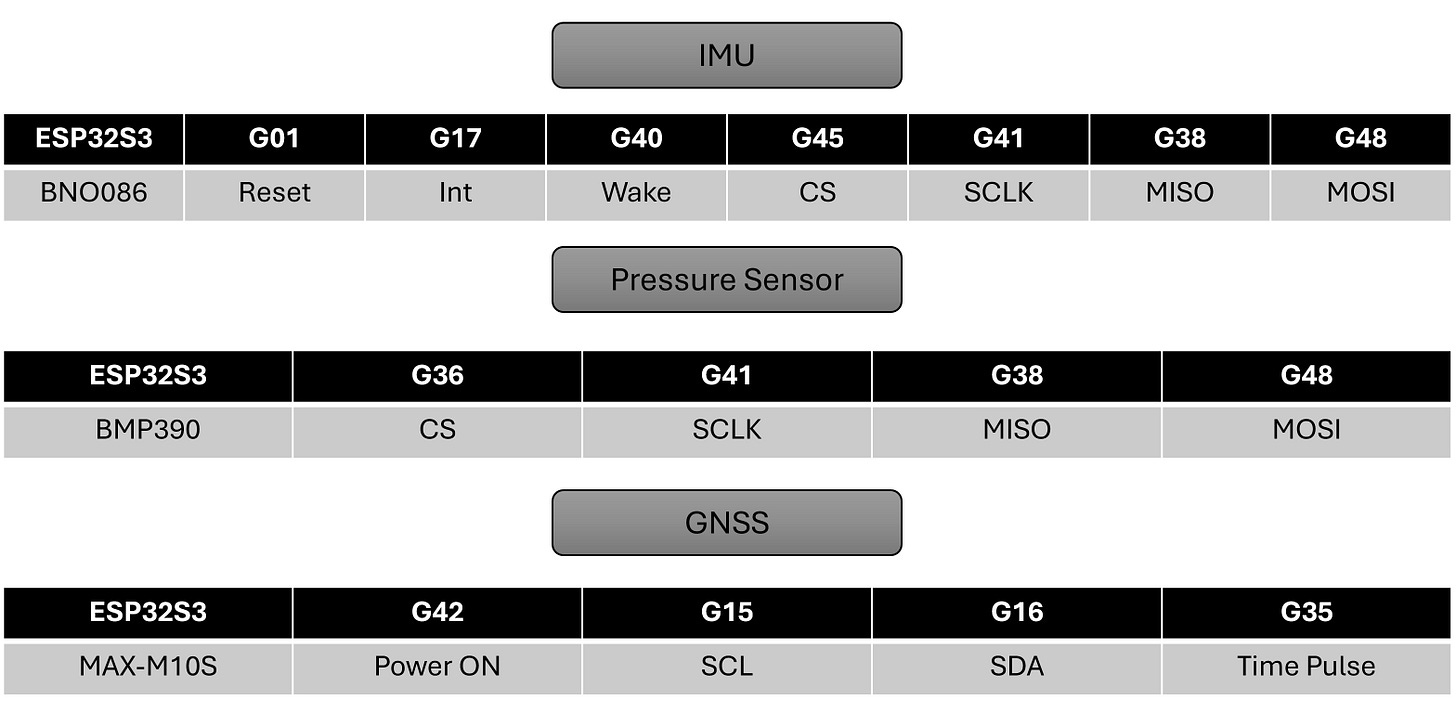

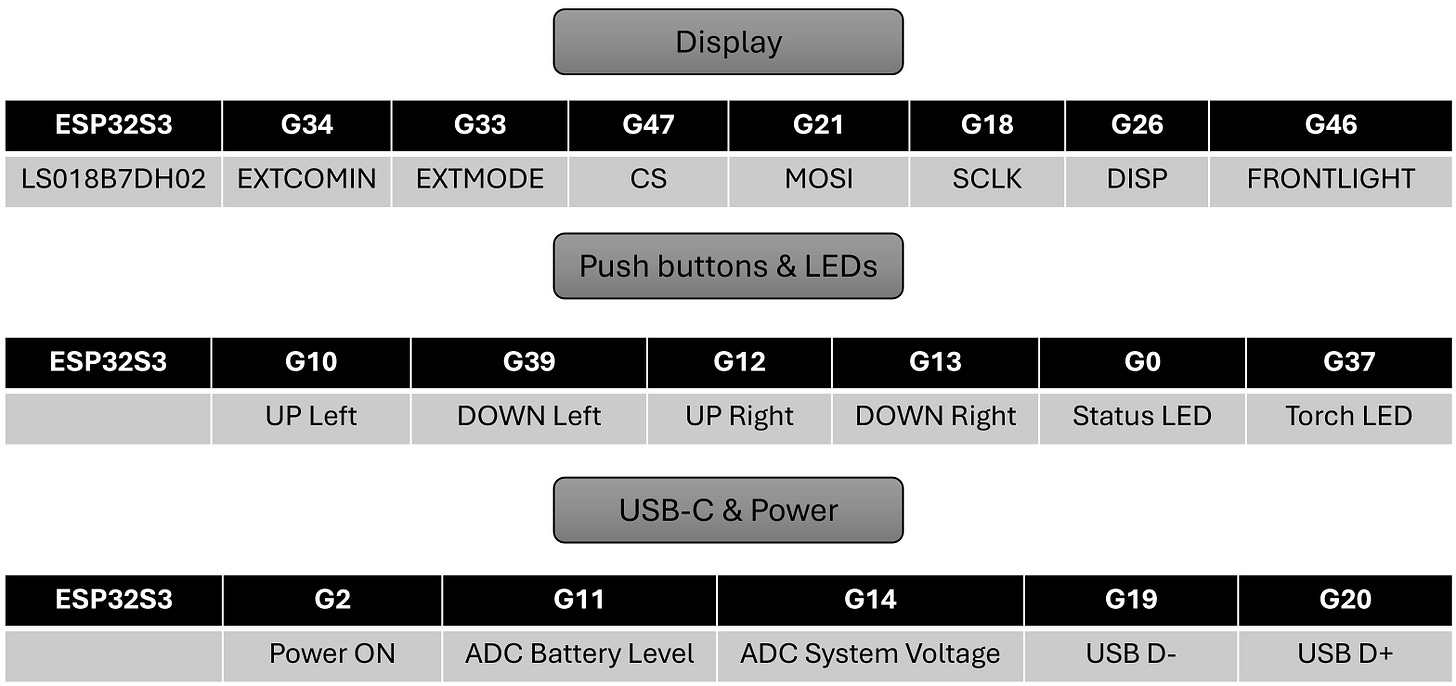

Below is the system-level diagram of the Pocket Tracker PCB. It shows how the ESP32-S3 is connected to all the onboard peripherals and external interfaces:

At the center, the ESP32-S3 manages everything, from sensors and display to power management and communication. Here's a quick overview of the key elements:

Sensors:

BNO086(IMU) andBMP390(pressure sensor) both use the same SPIGNSSis connected via I2C

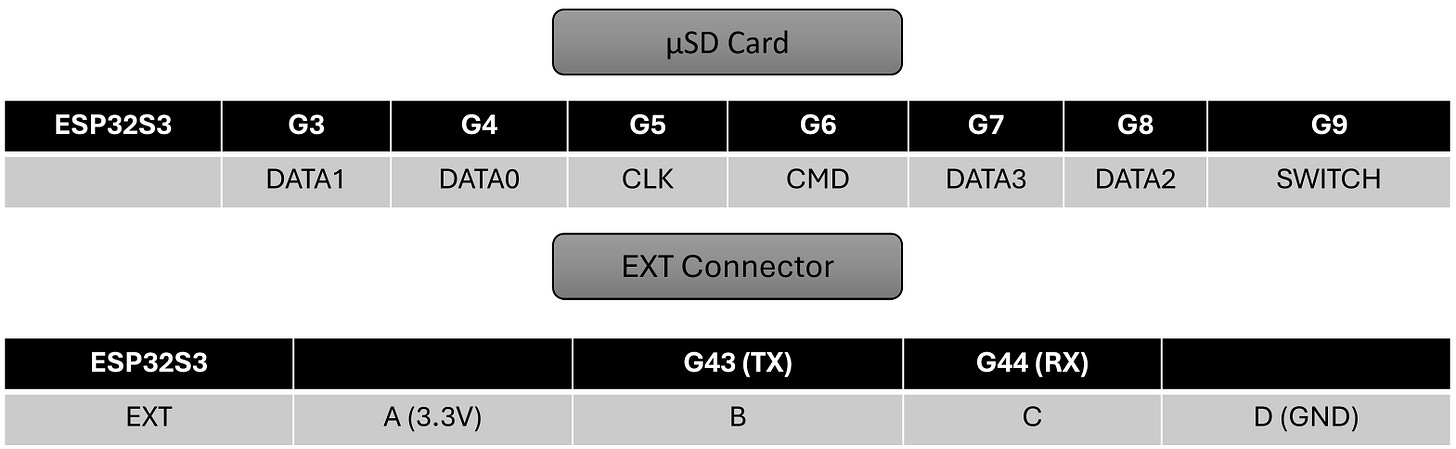

Storage & I/O:

uSD carduses the SDMMC interfaceExternal connector supports I2C, UART, GPIO for future add-ons

Display:

Controlled via SPI, with an additional line for frontlight control

Power:

Powered via USB-C or battery

Battery management and power path are handled by a dedicated circuit

A “Hold ON” control line keeps the system powered during runtime

Inputs & Outputs:

Pushbuttons, LED torch and status LED are controlled directly from the ESP32-S3

PIN MAP

I’m really curious to see what kind of things you’ll build with it — maybe custom sensors, data loggers, unique UI designs, or even outdoor tools.

5. Thanks & What’s Next

That’s all for this issue — thanks again for following along and for all the encouragement and ideas you've shared so far!

I’m currently working on expanding the Developer Zone on my website. It might sound like a simple task, but organizing all the resources in a way that’s clear and helpful—especially for those starting from scratch—is quite a challenge. My goal is to make it as easy as possible for you to understand, hack, and build with the Pocket Tracker.

So keep an eye out — the next issue will drop the moment the Pocket Tracker hits the Elecrow store! 🚀

Until then, grazie mille 🙏